How Do Different Electric Gate Types Work?

Electric gate types are varied and many but the basic designs use just two ways of operation. These are driveway gates that slide open or gates that swing open.

We will cover the different variants of both types of electric gates later in this blog. We will also cover the huge range of gate designs available.

But essentially, all the different types of electric gates either swing or slide.

What Are The Basic Types of Electric Gates?

Swing gates usually come in pairs that swing on hinges mounted to gate posts, pillars, piers or walls on opposite sides of the driveway. When swing gates are closed, they meet in the middle to block the full width of the entrance. Swing gates can be single gates for narrower drives, or when used as pedestrian gates. You can also have folding swing gates where space is limited.

Sliding gates are usually just a single gate leaf that slides across the driveway entrance. Sliding gates run on a track laid across the driveway entrance. They can also be installed in pairs and these usually meet in the middle of the drive. Sliding concertina gates slide against each other so they don’t need as much space to open into. Round the corner sliding gates are made of even more leaves, and cantilever sliding gates don’t need tracks.

How Do The Different Types of Electric Gates Operate?

Sliding gates are moved by a fixed motor with a toothed cog on its output shaft. This engages with a toothed rack installed along the length of the inside of the gate. When the motor turns the cog, it moves the gate on wheels along a track across the driveway entrance. Supports at either end keep it upright.

Swing gates work like doors. They are hung on hinges on one edge and they swing round in an arc. Two leaves meet in the middle of the drive. They are opened and closed by motors mounted on pillars or posts or installed underground in pits below the hinges. The motors rotate and arms and rods that connect them to the gate push and pull the gates open or closed.

If the arms attach to the gates close to the hinge, the force is applied inefficiently as it has to move the gates without much leverage advantage. If the motor arm applies its force to the gates further from the hinges, it has much more leverage and doesn’t need to be as strong.

Swing gates (particularly fully boarded ones that have no gaps) can be affected by strong winds. This electric gate type moves through at least 90 degrees as they open. They could start and finish with winds blowing on their surface from a completely different direction. This can stress motors and linkages and confuse obstacle detection systems.

How Much Space Do Different Electric Gate Types Need?

As an electric gate opens, it needs space to move into and this is where sliding gates and swing gates are quite different.

Sliding gates slide alongside walls or fences to one side of the gate opening. They need a length of continuous, straight track across the driveway opening and off to the side that is long enough for the open gate to completely clear the opening.

Swing gates move very little at their hinges but carve a large arc across the driveway at the other end. The space on the driveway that this electric gate type moves through needs to be clear of parked or waiting cars, plants, walls or any obstacle that the gates could hit.

Which Type Of Electric Gates Is The Safest?

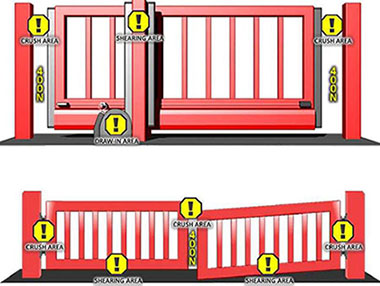

Automated swing gate and sliding gate systems are operated by powerful motors so they can create risk areas unless correctly designed and installed.

A sliding gate moves across other surfaces and there’s the possibility for shearing and crushing injuries if anyone gets an arm or leg caught. Swing gates can cause pinching and crushing injuries at the hinges and impact and crushing injuries as the gates swing open.

Because gravity pulls things downhill and slows their movement uphill, sliding gates should never be installed on a driveway that slopes across its entrance.

A qualified gate automation installation engineer will design and install the safest possible swing or sliding gate system for your unique requirements.

Read more about the safest electric gate types here.

Which Electric Gates Are Fastest?

Swing gates don’t move much at their hinges but the opposite end travels through a much longer arc. Even so, this distance is shorter than a sliding gate travels.

Using a 4m wide driveway as an example, a sliding gate moves more than this distance to completely clear the driveway when open.

However, the opening end of each pair of 2m long swing gates travels 3.141m to cover 90 degrees. Although these two types of gates move very differently and they have very different motors, swing gates usually open faster because each one doesn’t travel as far as the equivalent single sliding gate.

What Are The Different Varieties of Swing Gates?

Double Swing Gates

A standard pair of swing gates needs room for both leaves to move through as they open.

Single Swing Sate

Where the driveway is narrow it might be possible to install a single swing gate to cover the full width. Pedestrian gates are also nearly always single leaves.

Bi-fold swing gates

Bi-fold swing gates look like normal swing gates cut in half vertically and hinged to fold in the middle as they swing open. This means that this electric gate type needs just over half the space of traditional swing gates.

If you want swing gates but haven’t the room, bi-folds may be the option but there are a few things to consider.

Traditional bi-fold gates run on a track or a rail that guides the edge of the gates as they move. But overhead rails can be unattractive and limit the height of vehicles that can get through. And tracks need to be kept free of leaves and gravel.

These gates also need careful installation to make sure that they can travel without binding on the tracks or rails. There are new kits that do away with tracks or rails. These bi-fold gates also need to be installed accurately and they also need a close stop in the middle of the driveway.

Bi-fold gates use any standard automation motors such as articulated arm, rams, linear screw or underground gate motors.

Unequal Length Swing Gates

If there’s limited room on one side of a driveway, unequal length gates might be a possibility. However, this adds a lot of complexity to the system. Care must be taken with motor selection as two equal sized gates should weigh the same and require the same force to move them. However, a larger gate will weigh more than its smaller partner and need more force to move it.

What Are The Automatic Sliding Gate Options?

Single Leaf Sliding Gate

As well as a standard single leaf sliding gate, there are alternatives that are often used where space is limited and a large, single leaf sliding gate may not have enough room to open into. The alternatives include:

Bi-Parting Automatic Sliding Gates

A pair of sliding gates makes up bi-parting sliders that simply open in the middle and each leaf slides to one side. You need space either side of the opening, but it’s only half what’s required for a single sliding gate on one side of the driveway.

This arrangement is more expensive than a single gate leaf. You need two gate motors and a control unit to operate both. Two gates are usually more expensive to make than one and installation will cost more.

Round-The-Corner Sliding Gates

If space really is limited, round the corner sliding gates are more expensive but could be the ideal option. They are built up from multiple vertical gate sections with hinges on both edges. Each section usually has its own wheel, and the entire gate can follow a curved track.

So, if you have a wall or fence right next to your driveway opening, curved tracks allow a round-the-corner gate to follow the obstacle rather than hit it.

Telescopic Sliding Gates

Telescopic sliding gates are split into overlapping sections that neatly slide next to each other as the gate opens.

A triple leaf telescopic gate needs just over a third of the space a single leaf equivalent gate would require at the side of the driveway. A double leaf version would need just over half the space required for the single leaf slider.

With telescopic gates the section nearest the side of the driveway the gates open towards is the one powered by a standard sliding gate motor. The other gate sections are moved by cables that connect all the leaves together.

This is definitely going to cost more than the equivalent single sliding gate. Installation is complex, two, three or even four gate leaves are needed, and each gate leaf runs on its own track.

Cantilever gates

Cantilever gates need more space than standard sliding gates as they have a counterbalanced section added to one end that makes them even longer. However, they don’t need tracks to run on and are often used for wider entrances or uneven driveways.

What Makes The Perfect Gates?

Your perfect gates may be different from anyone else’s as we all have our own unique preferences and requirements. But considering the following possibilities can go some way to finding your perfect gates.

Design

A good place to start when selecting the design of your new electric gates is to look at the style of your house and those of your neighbours. Traditional gates could look out of place in front of a modern house and modern gates might jar at the entrance to a cottage.

Colour

Wooden gates can be supplied with a clear treatment or stain that helps to protect the wood from weathering for a while but needs regular reapplication. Painting gates gives similar protection and choice from a huge range of colours and shades. The choice means that you will always be able to match or compliment the colour of your house, walls or fences.

Iron and steel gates are traditionally finished in darker colours, and many are coated with specialist rust-preventing paints.

Aluminium gates are coated with a strong coating that is bonded to the gate surface. This layer provides the colour or wood-effect or steel-effect finish.

In all cases, the choices of colour are practically endless but only aluminium gates and wooden gates themselves provide a wood-grain finish.

What Are Different Types Of Gates Made From?

There are a few different materials gates can be made from and each has benefits and drawbacks. Wooden gates or gates made from iron or steel might be your first thought. Iron and steel gates tend to be ornate with thinner vertical and horizontal elements in an open boarded design. Wooden gates are more likely to be without gaps (solid boarded).

Wooden gates can rot, iron gates can rust, and both can be heavy. Steel gates are more resilient but also heavy and less varied in designs.

Aluminium is resilient to corrosion and can now be made to look remarkably like either iron or wooden gates.

Combinations of aluminium wood-effect panels in steel frames are also popular and look stylishly modern and somehow traditional at the same time.

As different woods, metals and plastics all lend themselves to different ways of building gates, the choice of what the gate is made of affects how it looks as well as how it resists the effects of the British weather.

Read more about wooden gates here.

How Does The Weather Affect Different Gate Types?

Some types of electric gates suffer from corrosion caused by wet weather more than others. There are also gate designs that are affected in other ways by weather conditions.

How Different Types Of Gates Are Affected By Weather

It might be stating the obvious but gates live in all weathers so they must be capable of dealing with rain, wind, snow and sunshine. Over a few days of varied weather, they can get wet, dry out and get wet again.

When it rains, wood soaks up water making it expand and get heavier. As it expands, it stretches bolt holes, paint and other coverings and pushes against neighbouring sections. When it dries, it shrinks back and becomes lighter. Eventually the surface coating cracks and joints open up to let even more water into the wood. Although regular treatment of can slow this down, wood will eventually rot.

Steel is more corrosion resistant but iron rusts when it gets wet. Various rust inhibitors and paints are available but once it’s set in, rust takes a lot of effort to treat effectively, and it will nearly always come back eventually.

Aluminium is much more resistant to corrosion than iron, and aluminium gates are also covered with a tough coating to provide even more protection. This coating is printed with the colour or wood-effect design that finishes your chosen gates’ design.

Open Or Close Boarded

For security and privacy, you may prefer gates that have no gaps in them. Wooden gates especially can be close boarded (no gaps) or open boarded (regular gaps) while iron and steel gates have a much more delicate design with many spaces.

If you live anywhere that experiences strong winds, gaps in your gates can be valuable. Without them, a solid gate can’t let the wind pass through it, so the full force blows against the gate. This gives your gate motors a hard time and the force they need to deliver to move the gates can dramatically change from moment to moment.

Our intention here was to give you a bit more information about the types of electric gates available.

If you still have any questions, please call us on 0800 195 1479 or email info@egrl.co.uk. You can also contact us here.